Ukukhusela amanzi angcono, emva kokufakwa kwebhodi efakwe umbala kugqityiwe, sebenzisa isixhobo esikhethekileyo sokusonga ibhodi efakwe umbala nge-3CM ngokubhekiselele kwi-ridge, malunga ne-800.

Iipaneli ezigqunywe ngombala ezithuthelwe kwi-truss yophahla azizange zifakwe ngokupheleleyo ngosuku olufanayo lokusebenza, ngoko ziqiniswe ngokuqinileyo kwi-truss yophahla lwentsimbi usebenzisa i-scaffolding. Ukuphunyezwa okuthe ngqo kunokuba kukusebenzisa iintambo ezimdaka okanye i-8 # iingcingo ezihamba phambili zokuzibopha ngokuqinileyo, eziya kuphepha nawuphi na umonakalo kwiipaneli ezigqunywe ngombala kwimozulu eqinile yomoya.

Isigqubuthelo sophahla kufuneka sakhiwe ngokukhawuleza emva kokugqitywa kwe-slab yephahla. Ukuba ayinakwakhiwa ngokukhawuleza, ilaphu leplastiki kufuneka lisetyenziswe ukukhusela imathiriyeli yokugquma kumqolo ophahleni ukuthintela ukuchatshazelwa kwefuthe leemvula.

Ngethuba lokwakhiwa kwepleyiti yesigqubuthelo se-ridge, kufuneka kuqinisekiswe ukuba ukutywinwa phakathi kwayo kunye nophahla, kunye naphakathi kwamacwecwe okugubungela umqolo, kunokwethenjelwa.

Xa uphakamisa uphahla kwi-truss yophahla ukufakela, nikela ingqalelo ekujongeni ubambo lomama webhodi egqunywe ngombala ukuya kwicala lokuqala lofakelo. Ukuba ayilobambo lomama, yilungise ngoko nangoko. Qinisekisa ukuba ujonga ukuthe tye kwebhodi yokuqala ukuya kumqolo kunye nophahla lwegutter ukuqinisekisa ukuba yonke imilinganiselo ichanekile.

Emva kwempazamo, lungisa i-plate yesiseko sokuqala kwaye ufake iipleyiti zesiseko ezilandelayo usebenzisa indlela efanayo, uhlala usebenzisa indawo yokuqinisekisa ukuba iziphelo zeplate egqunywe ngombala zicocekile kwaye zihamba ngokuthe tye.

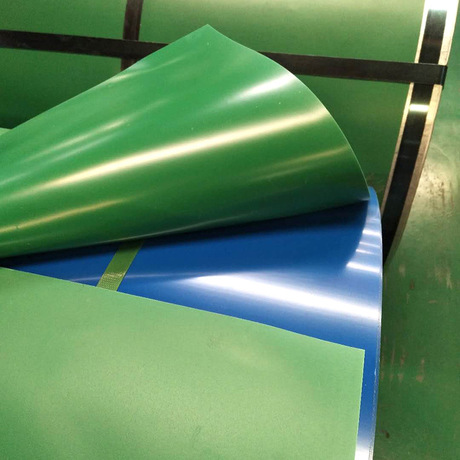

Ukufakwa kwebhodi efakwe umbala

(1) Yithuthe ngokuthe nkqo ibhodi, uqinisekise ukuba ubambo lukanina lujonge ekuqaleni kofakelo. Faka umqolo wokuqala wezibiyeli ezisisigxina kwaye uzilungise kwii-purlins zephahla, ulungelelanise isikhundla sabo, uqinisekise ukuchaneka kwendawo yokuqala yeplate ephezulu, kwaye ulungise umqolo wokuqala weebakaki ezisisigxina.

(2) Lungiselela ibhodi eqatywe ngombala wokuqala kwisibiyeli esisisigxina kwicala le-orthogonal ukuya kumjelo. Lungelelanisa ubambo oluphakathi kunye ne-engile yokugoba yesibiyeli esisisigxina, kwaye usebenzise iimbambo zeenyawo okanye ii-purlins zomthi ukuqhoboshela ubambo oluphakathi kunye nonina kwisibiyeli esisisigxina, kwaye ujonge ukuba zibotshelelwe ngokupheleleyo na.

(3) Khusela umqolo wesibini wezibiyeli ezingatshintshiyo kwimbambo zepleyiti eqatywe umbala esele zifakelwe uze uzifakele kwicandelo ngalinye lesibiyeli.

(4) Lungisa iimbambo zikanina zebhodi eqatywe umbala wesibini kumqolo wesibini wezibiyeli ezisisigxina, uze uziqinise ukusuka embindini ukuya kuzo zombini iziphelo. Faka ibhodi efakwe umbala ngendlela efanayo, ubeke ingqalelo kunxibelelwano oluthembekileyo kwaye ujonge ukuchaneka kokuma kunye nokuma kwephahla kwi-gutter nanini na.

(5) Ngethuba lenkqubo yofakelo, sebenzisa rhoqo imigca yokumisa ekupheleni kwebhodi ukuqinisekisa ukuhambelana kwebhodi efakwe umbala ngokwawo kunye ne-perpendicularity yayo kwi-gutter.

Ngexesha lofakelo, ingqalelo ekhethekileyo kufuneka ihlawulwe kula manqaku alandelayo:

(1) Umphezulu we-purlin osetyenziselwa ukuxhasa kufuneka ube kwindiza efanayo, kwaye indawo yayo inokulungiswa ngokucofa okanye ukuphumla ngokwemeko yangempela ukuhlangabezana nale mfuneko. Kunqatshelwe ngokungqongqo ukubetha ngokuthe ngqo inxalenye engezantsi ye-bracket esisigxina ekuzameni ukulungelelanisa i-slope okanye indawo yophahla. Ukubeka ngokuchanekileyo ibhodi epeyintiweyo kunokuqinisekisa ukuqina kwayo okusebenzayo. Ngokuchasene noko, ukuba ibhodi epeyintiweyo ayihambelani ngokufanelekileyo, iya kuchaphazela umphumo wokuqiniswa kwebhodi epeyintiweyo, ngokukodwa kufuphi nendawo ephakathi yenkxaso.

(2) Ukuze kuthintelwe ukwenziwa kweebhodi ezipeyintiweyo ezimile njengefeni okanye ezisasazekileyo okanye imiphetho engalinganiyo yophahla ngenxa yolwakhiwo olungafanelekanga, iibhodi ezipeyintiweyo kufuneka zitshekishelwe ulungelelwaniso olufanelekileyo kunye nomgama osuka kumaphethelo aphezulu nasezantsi. iibhodi ezipeyintiweyo kumjelo womlambo kufuneka zilinganiswe ngamaxesha onke ukuphepha ukuthambeka.

(3) Ngoko nangoko coca nawaphi na amathontsi amanzi aseleyo, iirivet rods, iifasteners ezilahliweyo, kunye nolunye udaka lwentsimbi eluphahleni emva kokufakwa, njengoko le nkunkuma yentsimbi inokubangela ukubola kweepaneli ezipeyintiweyo.

Ukwakhiwa kwezixhobo ezifana neekona kunye nokukhanyisa

2. Ukubekwa komqhaphu wokugquma:

Ngaphambi kokubeka, ubukhulu bomqhaphu we-insulation kufuneka buhlolwe ukufana, kwaye isatifikethi sokuqinisekiswa komgangatho kunye nesatifikethi sokuhambelana kufuneka sihlolwe ukuthotyelwa kweemfuno zoyilo.

Xa ubeka i-cotton ye-insulation, kufuneka ibekwe ngokuqinileyo, ingabikho izikhewu phakathi kwekotoni ye-insulation kunye nokulungiswa ngexesha elifanelekileyo.

3. Ukubekwa kweelebhu yophahla:

Xa ubeka iipaneli zangaphakathi kunye nangaphandle kwephahla, ukugqithwa komphetho ngamnye kuya kuqhutywa ngokungqongqo ngokuhambelana neenkcukacha. Xa ufaka i-eaves, indawo yofakelo iya kugqitywa ngokudibanisa ipleyiti engezantsi kunye noboya beglasi. Ufakelo luya kuqala kwi-eaves kwaye lubekwe ngokulandelelana ukusuka ezantsi ukuya phezulu. Ukuhlolwa kwecandelo kuya kwenziwa ukujonga ukuthambeka kweziphelo zombini kunye nokuthe tyaba kweepaneli ukuqinisekisa ukufakwa.

Umgangatho.

4. Amaphepha e-SAR-PVC angenawo amanzi angasetyenziselwa ukunkcenkceshela okuthambileyo kwiindawo ezifana neengqungquthela eziphahleni kunye neengqungquthela, ezinokuthi zicombulule ngokufanelekileyo iingxaki zokubambisana kunye nokuvuza kwamanzi angenakusombululwa ngombala weplate yombala. Indawo yokulungisa i-PVC roll material iqinisekiswa ukuba igxininiswe kwi-peak surface yebhodi yeprofayili, iqinisekisa ukuba iindawo zokulungisa zixhomekeke kumandla afanelekileyo kunye nesakhiwo esingenamanzi sinengqiqo.

5. Ulawulo lokufakela ipleyiti yentsimbi eneprofayili:

① Ufakelo lwamacwecwe esinyithi aneprofayili kufuneka ibe mcaba kwaye ithe tye, kwaye akufuneki kubekho intsalela yokwakha okanye ubumdaka kumphezulu wepleyiti. I-eves kunye nesiphelo esisezantsi sodonga kufuneka sibe kumgca othe tye, kwaye akufuneki kubekho imingxuma egrunjwayo.

② Ubungakanani bokuhlolwa: I-10% yendawo kufuneka ihlolwe ngokungacwangciswanga, kwaye akufanele ibe ngaphantsi kweemitha ezili-square ezili-10.

③ Indlela yokuhlola: Ukuqwalaselwa kunye nokuhlola

④ Ukutenxa ekufakeni iipleyiti zentsimbi ezineprofayili:

⑤ Ukutenxa okuvumelekileyo kofakelo lwamacwecwe esinyithi aneprofayili kuya kuhambelana namalungiselelo akwitheyibhile engezantsi.

⑥ Ubungakanani bokuhlolwa: Ukuhambelana phakathi kwe-eves kunye ne-ridges: i-10% yobude kufuneka ihlolwe ngokungenamkhethe, kwaye kufuneka ingabi ngaphantsi kwe-10m. Ezinye iiprojekthi: Ukuhlolwa kwendawo enye kufuneka kuqhutywe rhoqo kwiimitha ezingama-20 ubude, kwaye kufuneka kungabi ngaphantsi kwamabala amabini.

⑦ Indlela yokuhlola: Jonga ngocingo, ucingo lokuxhoma, kunye nerula yentsimbi.

Ukutenxa okuvumelekileyo kufakelo lweepleyiti zentsimbi ezineprofayili (mm)

Ukutenxa okuvumelekileyo kweprojekthi

Ixesha lokuposa: Nov-05-2024