Ibhodi egqunywe ngombala yinto yokwakha eluhlaza kunye nokusingqongileyo. Indlela yokuyikhetha ngokuchanekileyo, ukuyisebenzisa ngokufanelekileyo, kunye nokuphucula ubomi bayo benkonzo ngumcimbi ochaphazelekayo kubanini kunye nabakhi bobunjineli. I-Baosteel, njengenkqubo epheleleyo yesityalo sentsimbi, inamava atyebileyo kwimveliso kunye nokusetyenziswa kwamacwecwe afakwe umbala. Imodyuli ethi "UKhetho lweMathiriyeli yeNzululwazi" ibonelela ngengcebiso emfutshane kunye nentshayelelo kubasebenzisi ekukhetheni nasekusebenziseni iipleyiti ezinombala.

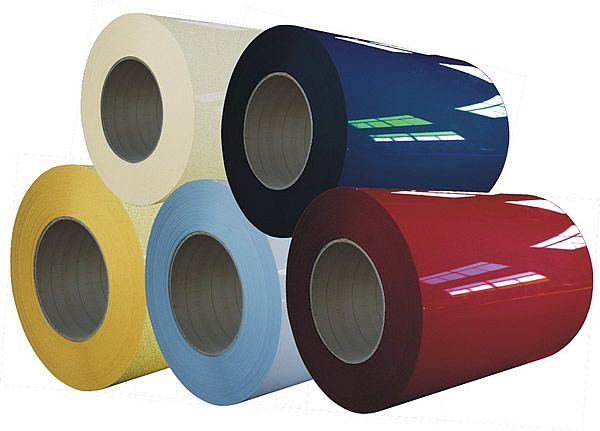

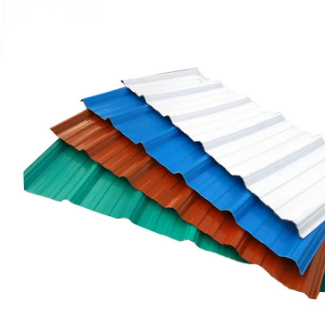

Ukhetho oluchanekileyo lweepaneli ezigqunywe ngombala kufuneka ziqwalasele indawo yendalo, indawo yokusetyenziswa, ubomi bokuyila, kunye neempawu zesakhiwo sesakhiwo, ukwenzela ukuba ukhethe uhlobo lwentsimbi, ukucaciswa, ukugubungela, kunye neengubo ezihambelana nayo. Abayili bezakhiwo, abanini bobunjineli, kunye nabaprosesa baqwalasela ukusebenza kokhuseleko (ukumelana nempembelelo, ukuxhathisa kwenyikima, ukuxhathisa umlilo, ukumelana noxinzelelo lomoya, ukumelana nekhephu), ukusebenza kwendawo yokuhlala (ukungangeni kwamanzi, ukugquma isandi, ukugquma), ukuqina (ukumelana nongcoliseko, ukuqina, ukugcinwa kwembonakalo) , kunye noqoqosho (ixabiso eliphantsi, ukusetyenzwa lula, ukugcinwa lula, kunye nokutshintshwa okulula) kwezakhiwo. Kubathengisi beepleyiti zetsimbi ezifakwe umbala, ezi zakhiwo kufuneka ziguqulwe zibe ziimpawu zeplate yentsimbi efakwe umbala ngeentsimbi zetsimbi kwaye ziqinisekisiwe. Iimfuno zokusebenza zeepleyiti zentsimbi ezigqunywe ngombala zibandakanya ubukhulu becala iipropathi zoomatshini (amandla okuqina, amandla emveliso, ukomelela), ukusebenza kokugquma (uhlobo lokutyabeka, ukutyeba kokutyabeka, kunye nokuncamathela), kunye nokusebenza kokwambathisa (uhlobo lokutyabeka, umbala, isilungiseleli seglosi). , ukuqina, ukuqhubekeka, njl njl.). Phakathi kwazo, ukuxhathisa umoya, ukumelana nempembelelo, ukuxhathisa kwekhephu, ukuxhathisa inyikima, njl.njl. zonke zinxulumene neempawu zomatshini wezinto, kwaye, ngokuqinisekileyo, zikwanxulumene nokwakheka kwamaza, ubukhulu, ubude, kunye nesithuba seepleyiti zentsimbi ezinombala. . Ukuba iipleyiti zentsimbi ezinombala ezifanelekileyo zikhethiwe kwaye zidityaniswe noyilo olufanelekileyo lweprofayili yentsimbi, ayinakuhlangabezana nokhuseleko lwezakhiwo kuphela kodwa ikwanciphisa iindleko zobunjineli. Ukomelela, ukusetyenzwa kwentsebenzo, kunye nokugcinwa kwenkangeleko yemathiriyeli ubukhulu becala kumiselwa kukuqina kweengubo kunye neengubo.

Iintlobo zokwaleka

Okwangoku, iintlobo zokugquma ezisetyenziselwa iipleyiti zentsimbi ezigqunywe ngombala ziquka i-polyester (PE), i-fluorocarbon coating (PVDF), i-silicon modified coating (SMP), i-high weather resistance (HDP), i-acrylic acid, i-polyurethane coating (PU) , iplastiki yokugquma ngentsimbi (PVC), njl.

Ipolyester eqhelekileyo (PE, iPolyester)

Ukwaleka kwe-PE kunokubambelela kakuhle kwizinto eziphathekayo, kwaye iipleyiti zentsimbi ezigqunywe ngombala kulula ukusetyenzwa kunye nokwenza, zingabizi kakhulu, kwaye zineemveliso ezininzi. Kukho uluhlu olubanzi lweenketho zombala kunye neglosi. Ngaphantsi kokuvezwa ngokuthe ngqo kwiindawo eziqhelekileyo, ubomi bayo obuchasene ne-corrosion bunokufikelela kwiminyaka eyi-7-8. Nangona kunjalo, kwiindawo zoshishino okanye kwiindawo ezingcoliseke kakhulu, ubomi bayo benkonzo buya kuncitshiswa. Nangona kunjalo, iingubo zepolyester azifanelekanga ukuchasana kwe-UV kunye nokumelana nomgubo wefilimu. Ke ngoko, ukusetyenziswa kweengubo ze-PE kusafuneka kuncitshiswe, kwaye zisetyenziswa ngokubanzi kwiindawo ezinongcoliseko oluncinci lomoya okanye iimveliso ezifuna ukubunjwa okuninzi kunye nokusebenza.

I-Silicone Modified Polyester (SMP)

Ngenxa yobukho bamaqela asebenzayo - OH / - COOH kwi-polyester, kulula ukusabela kunye nezinye iipolymers kunye nezinto. Ukuze kuphuculwe ukumelana nokukhanya kwelanga kunye nokucolwa kwe-PE, i-silicone resin enokugcina umbala obalaseleyo kunye nokumelana nobushushu isetyenziselwa ukusabela kwe-denaturation. Umlinganiselo we-denaturation kunye ne-PE unokuba phakathi kwe-5% kunye ne-50%. I-SMP inika ukuqina okungcono kwiiplate zetsimbi, kunye nobomi bokumelana nokubola ukuya kuthi ga kwi-10-12 iminyaka. Kakade ke, ixabiso layo liphezulu kunelo le-PE, Nangona kunjalo, ngenxa yokunganeliseki kokunamathela kunye nokuqulunqwa kwe-Silicone resin kwizinto eziphathekayo, iipleyiti zensimbi ezinombala we-SMP azifanelekanga kwiimeko ezifuna iinkqubo ezininzi zokubumba, kwaye zisetyenziselwa ubukhulu becala. ukwakha uphahla kunye neendonga zangaphandle.

Ipolyester exhathisa imozulu ephezulu (i-HDP, ipolyester ephezulu ehlala ixesha elide)

Ngokuphathelele ukusilela kwe-PE kunye ne-SMP, inkampani yaseBrithani i-HYDRA (ngoku efunyenwe yi-BASF) kunye nenkampani yaseSweden i-BECKER yavelisa iingubo ze-HDP ze-polyester ekuqaleni kwe-2000 ezinokufikelela kwi-60-80% yokuchasana kwemozulu kwiingubo ze-PVDF, kwaye ziphezulu kune-silicon eqhelekileyo yokuguqulwa kwe-polyester. . Ukumelana kwabo nemozulu yangaphandle kufikelela kwiminyaka eyi-15. I-resin ye-polyester echasene nemozulu ephezulu idityaniswe kusetyenziswa i-monomers equkethe isakhiwo se-cyclohexane ukufezekisa ukulingana phakathi kokuguquguquka, ukumelana nemozulu, kunye neendleko. Iipolyols zasimahla kunye neeasidi ezinuka kamnandi zisetyenziselwa ukunciphisa ukunyuswa kokukhanya kwe-UV nge-resin, ukufezekisa ukuchasana kwemozulu ephezulu kwengubo. Ukongezwa kwee-absorber ultraviolet kunye ne-steric hindrance amines (HALS) kwifomula yokugqoka iphucula ukuchasana kwemozulu yefilimu yepeyinti. I-coil ye-coil ye-coil echasene nemozulu ephezulu iye yaqatshelwa yimarike yangaphandle, kwaye indleko yayo iyasebenza kakhulu.

Iplastiki yePVC

I-resin ye-PVC inokumelana kakuhle namanzi kunye nokumelana neekhemikhali, kwaye ngokubanzi igqunywe ngomxholo ophezulu oqinileyo, kunye nobukhulu bokugquma obuyi-100-300 μ Phakathi kwe-m, inokubonelela nge-PVC egudileyo yokwaleka okanye unyango olulula njenge-embossing; Ngenxa yokuba i-PVC yokugqoka i-resin ye-thermoplastic kunye nobukhulu befilimu ephezulu, inokubonelela ngokukhuselekileyo kwiipleyiti zetsimbi. Kodwa i-PVC inokumelana nobushushu obubuthathaka. Ngeentsuku zokuqala, yayisetyenziswa kakhulu eYurophu, kodwa ngenxa yeempawu zayo zokusingqongileyo, ngoku isetyenziswa kancinci nangaphantsi.

I-PVDF i-fluorocarbon

Ngenxa yamandla okudibanisa okuqinileyo phakathi kweekhemikhali ze-PVDF, i-coating inokumelana ne-corrosion kunye nokugcina umbala. Yeyona mveliso iphambili kushishino lokwakha umbala ogqunywe ngepleyiti yentsimbi, enobunzima bemolekyuli kunye nesakhiwo sebhondi ethe tye. Ke ngoko, ukongeza ukuchasana neekhemikhali, iipropathi zoomatshini, ukuxhathisa kwe-UV, kunye nokumelana nobushushu nazo zibalulekile

Ukukhetha i-primer, kukho izinto ezimbini ezibalulekileyo. Enye kukuqwalasela ukunamathela phakathi kwe-primer kunye ne-topcoat, kunye ne-substrate. Enye into yokuba i-primer inika uninzi lokumelana nokugqwala kwengubo. Ukusuka kulo mbono, i-epoxy resin lolona khetho lungcono. Ukuba uqwalasela ukuguquguquka kunye nokuchasana kwe-UV, i-polyurethane primer nayo inokukhethwa.

Ukugquma ngasemva, olona khetho luchanekileyo kukukhetha ulwakhiwo lwamaleko amabini, oko kukuthi, umaleko omnye we-primer yangasemva kunye nomqolo omnye we-topcoat yangasemva, ukuba ipleyiti yentsimbi efakwe umbala ikwimo yebhodi enye. I-primer kunye nephambili yeentlobo ezahlukeneyo, kwaye isambatho esiphezulu kufuneka sibe nombala okhanyayo (njengomhlophe) i-polyester. Ukuba ipleyiti yensimbi efakwe umbala ikwimo edibeneyo okanye isandwich, kwanele ukusebenzisa umaleko we-epoxy resin kunye nokubambelela okugqwesileyo kunye nokumelana nokubola ngasemva.

Okwangoku, kukho iipleyiti zentsimbi ezinombala osebenzayo, ezifana nombala we-antibacterial, i-anti-static color coloring, i-thermal insulation color coating, i-self-coca color coloring, njl njl. Uphuhliso lwezi mveliso lujolise ekuhlangabezaneni neemfuno ezikhethekileyo ze abasebenzisi, kodwa ngamanye amaxesha akwenzeki ukulungelelanisa enye intsebenzo yeemveliso ezigqunywe ngombala. Ke ngoko, xa abasebenzisi bekhetha iipleyiti zentsimbi ezinombala osebenzayo, kufuneka bacace malunga neemfuno zabo zokwenyani.

Ixesha lokuposa: Sep-18-2023